Brief description of equipment

-

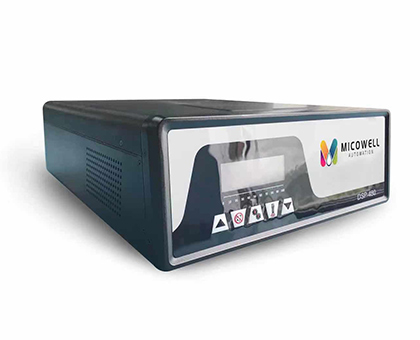

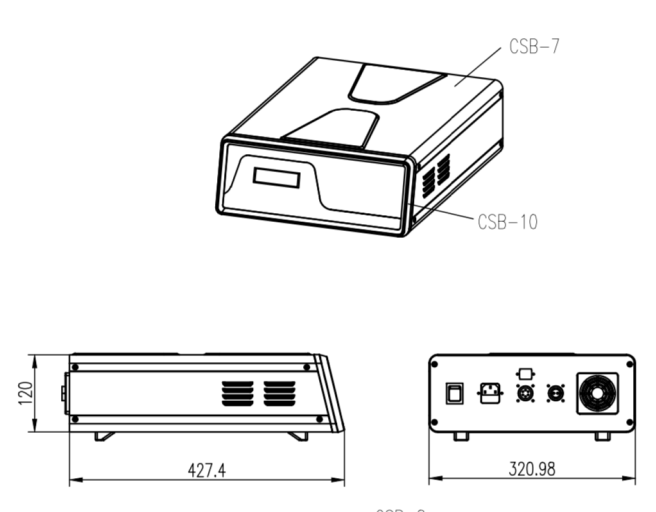

DSP series intelligent ultrasonic power generator has the highest power-to-volume ratio (that is, it can provide the largest power output in the smallest space). And it also provides a variety of installation methods to facilitate the flexible use of automation users. On the model. According to the different frequency power, size and installation method (horizontal installation and vertical installation), DSP is divided into fourteen models, specifically: 1250W at 20kHz. 2500W and 3500W; 800W and 1200W at 40kHz; 400WK and 600W at 50kHz. Not only can it be used in conjunction with a standard ultrasonic rack, but it can also be directly matched with the ultrasonic triplet composed of transducer/amplifier/welding head. DSP series intelligent ultrasonic power generator has the highest power-to-volume ratio (that is, it can provide the largest power output in the smallest space). And it also provides a variety of installation methods to facilitate the flexible use of automation users. On the model. According to the different frequency power, size and installation method (horizontal installation and vertical installation), DSP is divided into fourteen models, specifically: 1250W at 20kHz. 2500W and 3500W; 800W and 1200W at 40kHz; 400WK and 600W at 50kHz. Not only can it be used in conjunction with a standard ultrasonic rack, but it can also be directly matched with the ultrasonic triplet composed of transducer/amplifier/welding head.

What should I do if the generator or transducer fails?

How to deal with the problems that often occur in the transducer of ultrasonic cleaners?

What should I do if the generator or transducer fails?

How to deal with the problems that often occur in the transducer of ultrasonic cleaners?